FLINT, MI – Lear breaks ground on the first new greenfield automotive-supplier plant here in 30 years, as it plans to shift seating work for GM pickups from nearby Rochester Hills to help revitalize this downtrodden area.

“Now we can talk about what’s going to be,” Gerald Kariem, director of UAW Region 1D, says of how locals reminisce about Flint’s manufacturing past.

The new Lear seating facility, set to begin initial production in April and reach full production by 2019, will be located on a portion of General Motors’ former Buick City complex, at one time the largest automotive manufacturing complex of its kind in the world and which closed in 1999.

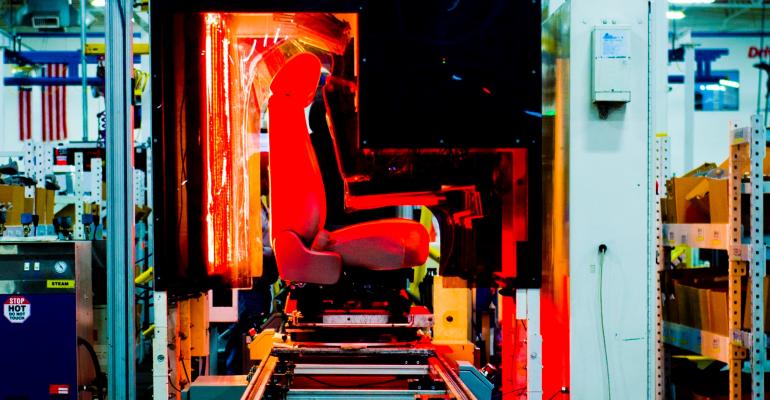

The new 156,000-sq.-ft. (14,493-sq.-m) facility will supply GM’s Flint Truck assembly plant, but Lear representatives refuse to name specific models. GM builds the heavy-duty version of the Chevrolet Silverado and GMC Sierra pickups in Flint, as well as the light-duty Silverado.

Lear’s Rochester Hills seating plant, which currently has the business for Flint Truck, will continue to operate with “incremental business,” Jason Scott, global vice president-Lear’s GM seating group, tells WardsAuto.

Of the 600 employees set to work at the new plant, Lear expects roughly 165 to shift from Rochester Hills to here, but emphasizes 435 jobs will be workers new to Lear in the state.

“One thing we know is, to recover from the crisis we have been in, is we needed some jobs to come to Flint,” Mayor Karen Weaver tells the crowd, alluding to the loss of automotive manufacturing in the city as well as Flint’s lead-tainted water scandal.

Scott notes the plant will be larger than some other Lear seating plants, including Rochester Hills, due to having assembly and sub-assembly areas.

Scott, as well as Lear seating business President Ray Scott, hopes Lear’s investment will be a catalyst for others from its supply base to locate nearby.

Ray Scott grew up in Flint and tells the crowd, “It’s just a city that keeps fighting back,” and adds he and representatives from GM worked for a year-and-a-half on getting the new location.

As with most new automotive manufacturing facilities, state funding is helping offset some of Lear’s costs. The Michigan Strategic Fund board approved a $4.35 million Michigan Business Development Program grant offsetting Lear’s $29.3 million site investment.

The Flint Journal reported in August the city of Flint offered a 50% tax abatement to Lear and the supplier had considered moving the Rochester Hills GM business to Mexico before selecting Flint.

This will be the first new Lear seating facility in Michigan in 25 years and its first new seating facility in the U.S. since the supplier opened its Tuscaloosa, AL, location to support Mercedes-Benz in 2012, says Jason Scott.

With the contraction in automotive seating in recent years – Johnson Controls divested its seating business, now known as Adient – Jason Scott says Lear believes seating “is a growth industry.

“You’ve got to perform well, but that’s any market that you’re in (and) we believe we’re well situated with our component groups and, really, the vastness of our component groups.

“We’re the only one that has textile, leather, structures and the electrical business (and that) situates us well. You don’t touch anything more than you do in a seat.”