AUBURN HILLS, MI – Stop/start systems are becoming popular, especially in hybrids and in Europe, as a way to conserve fuel when idling.

But shutting down the engine often means turning off the air conditioning, which can cause discomfort quickly on a sweltering day.

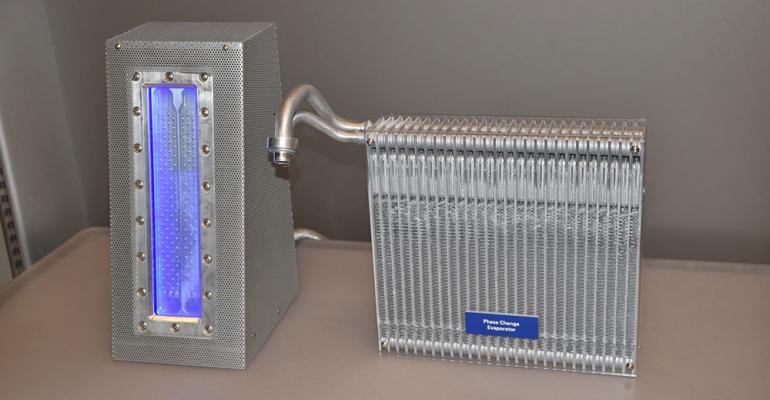

Delphi’s solution is its new Cold Storage Evaporator, which goes into production next year and can keep the cabin cool up to two minutes while the engine is off, says Erich Becker, systems engineering manager for Delphi Thermal.

Other systems currently on the market are able to provide that cooling for up to 1 minute, he says.

Shutting down the engine means turning off the engine-driven compressor, which prevents refrigerant from circulating in the evaporator, causing interior temperatures to rise quickly.

Delphi’s system applies a patented thermosiphon process to refrigerant already inside in the evaporator to initiate an additional heat-transfer mode.

The device captures energy produced when the AC is running under normal conditions and uses it to recharge and freeze a phase-change material located within the upper chamber of the evaporator.

When the engine and compressor shut off, the thermal expansion valve that meters the refrigerant flow to and from the evaporator also turns off, trapping refrigerant inside the evaporator.

At this point, the phase-change material begins to melt as it is warmed by the trapped refrigerant, which falls within the evaporator and will rise again as it warms to repeat the cycle. This is Delphi’s patented thermosiphoning effect.

The result is stored cool air coursing through the vents even when the compressor and engine are not running. The blower continues operating while the vehicle is stopped. “It’s almost like a battery,” Becker says. “We store thermal energy.”

The system continues producing cool air until the ambient cabin temperature rises to a certain threshold determined by the OEM customer. At that point, the engine will turn back on and cool the interior conventionally.

When the engine restarts, the phase-change material will recharge within 30 seconds with stored cold air the next time the engine shuts off.

Delphi says a stop/start micro-hybrid equipped with the Cold Storage Evaporator will be able to remain off 95% of the time during idle stops compared with 40% for vehicles with competitive systems. The result is tailpipe carbon-dioxide emissions reduced by 3.3g per mile.

The product starts as a standard brazed aluminum evaporator – Delphi has produced millions of them in the climate-control sector – that grows about 20% taller to house additional flow chambers for the phase-change material, Becker says.

Delphi’s device has the advantage of packaging the phase-change material out of the air stream while competitive systems place the material directly in the air stream, he adds.

“That’s an additional penalty to the system,” Becker says. “As you add material in the air stream, the power consumption for your blower motor must increase to overcome that added resistance. Because ours is out of the air stream, you see the same exact resistance you’d see in a normal evaporator.”

Delphi declines to identify its first customer for the system.