Christian von Koenigsegg has been building some of the fastest and most technologically advanced cars available at any price since 1994. His latest creation is a spinoff business called FreeValve, which is producing an engine with no camshafts.

Chinese luxury automaker Qoros debuted the engine in a concept car at the Beijing auto show in April 2016. A car with the “Qamfree” engine was driven onto the Qoros stage at the Guangzhou auto show in November.

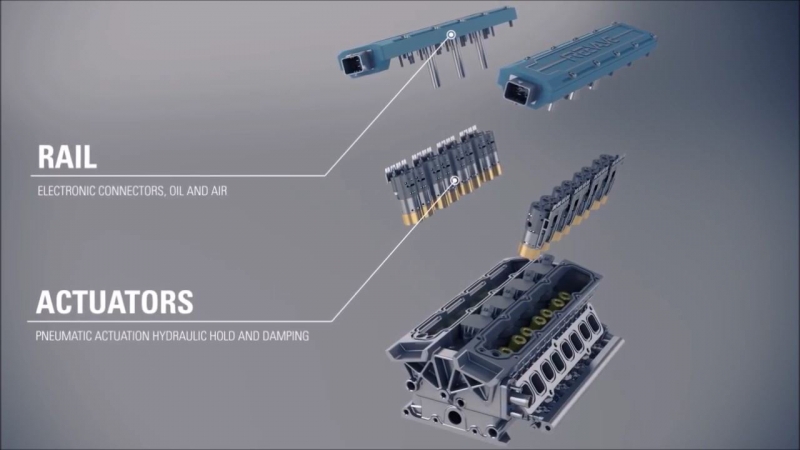

A rotating camshaft (or two, per cylinder bank) actuates the valves in a standard internal-combustion engine. In the FreeValve engine, the valves are opened and closed by a system that includes electronic actuators with pneumatic and hydraulic controls.

An electrical impulse is sent to the valve’s solenoid, causing the valve to open. A combination of air and hydraulic pressure stabilize the opening of the valve, damping any oscillations caused by the solenoid. The air and hydraulic pressure also determine how wide the valve opens. When the electrical signal is removed from the solenoid, the hydraulic pressure causes it to close.

When a camshaft opens and closes a valve, the cam profile doesn’t allow the valve to completely open or close at once. As the cam rotates, the lift generated by the cam lobe increases until the valve is fully open and the valve then closes in the same fashion.

With FreeValve’s camless design, the valve completely opens and closes almost instantaneously. This makes for a much more efficient fuel-air mixture.

Automakers and suppliers such as Valeo and Eaton have been experimenting with camless engines over the years for a number of reasons. Because a camless engine has fewer moving parts, there is less friction. Less friction means needing less power to overcome that friction.

A camless design also means the engine can be smaller and lighter, and therefore it doesn’t have to work as hard to overcome inertia when the vehicle is accelerating. Overall, the FreeValve/Qoros engine realizes a weight reduction of 44 lbs. (20 kg), the automaker says.

The FreeValve engine was installed in a Qoros 3 hatchback when it was unveiled at the Beijing show. With the FreeValve modifications, the 1.6L turbocharged engine was able to achieve a 47% increase in output to 230 hp; a 45% increase in torque, to 236 lb.-ft. (320 Nm); and a 15% reduction in fuel consumption, the company says.

The design of a camshaft’s lobes makes it impossible to completely scavenge every trace of residuals from a standard engine’s cylinders. The FreeValve engine’s four valves per cylinder – two intake and two exhaust – can be controlled individually, and the slightly differing designs of each cylinder’s exhaust ports, allows 100% of the combustion residuals to be scavenged from the cylinders.

This means volumetric efficiency can be increased, and knock can be reduced or eliminated at any compression ratio. Finally, the two intake ports for each cylinder have slightly different designs to ensure the air-fuel mixture achieves maximum atomization and, in turn, maximum intake runner inertia and lower internal temperatures, FreeValve says. Port design contributes to a 30% increase in volumetric efficiency over single- and dual overhead cam engines of the same displacement.

Because everything associated with the camshaft assembly is eliminated, including the timing assembly, gears, chain/belt and cover, production and installation costs also are lower. In the FreeValve engine, only one valve per cylinder feeds the turbocharger. This means exhaust outlet pressures can be controlled more accurately than with a wastegate, leaving no need for the wastegate and its associated controls and plumbing.

The pre-catalytic converter also can be done away with. At cold start, the FreeValve engine’s exhaust valves can be opened so as to bypass the turbocharger, causing the catalytic converter to heat up more quickly.

Savings also are realized in the FreeValve engine’s fuel system, as the engine uses port injection instead of more-costly direct injection. Less-expensive fuel pumps and regulators can be used because port injection functions with lower pressure at the fuel rail.

One problem with engines equipped with timing belts is that major internal damage can be done to the engine when the belt slips or breaks. This problem is eliminated in the FreeValve engine because it has no rotating assembly associated with the valves. If the system that controls the valves fails, the engine simply stops running and the valves remain in the fully closed position. This means there is no risk of bent valves or damaged pistons. Tests of the valve actuators have shown no measurable wear after hundreds of millions of cycles, giving them the same life expectancy of a current engine, FreeValve says.

“This production-intent engine (in the Qoros 3 hatchback at the Guangzhou show) offers Qoros significant savings in emissions, cost and weight,” FreeValve CEO Urban Carlson says. “It also offers groundbreaking benefits to vehicle owners in terms of a near-50% increase in both power and torque while actually reducing fuel consumption.”

Adds von Koenigsegg, CEO of Koenigsegg Automotive and chairman of the FreeValve board: “This move closer to mass production of FreeValve technology is also a first baby step towards the promise of important reductions in (carbon dioxide) emissions. This will be boosted with the eventual widespread adoption of FreeValve technology in the automotive industry.

“We believe that one day in the very near future, the arrival of FreeValve PHE (pneumatic-hydraulic electric actuator) technology will represent as big a transition, or bigger, than the move from carburetors to direct injection.”